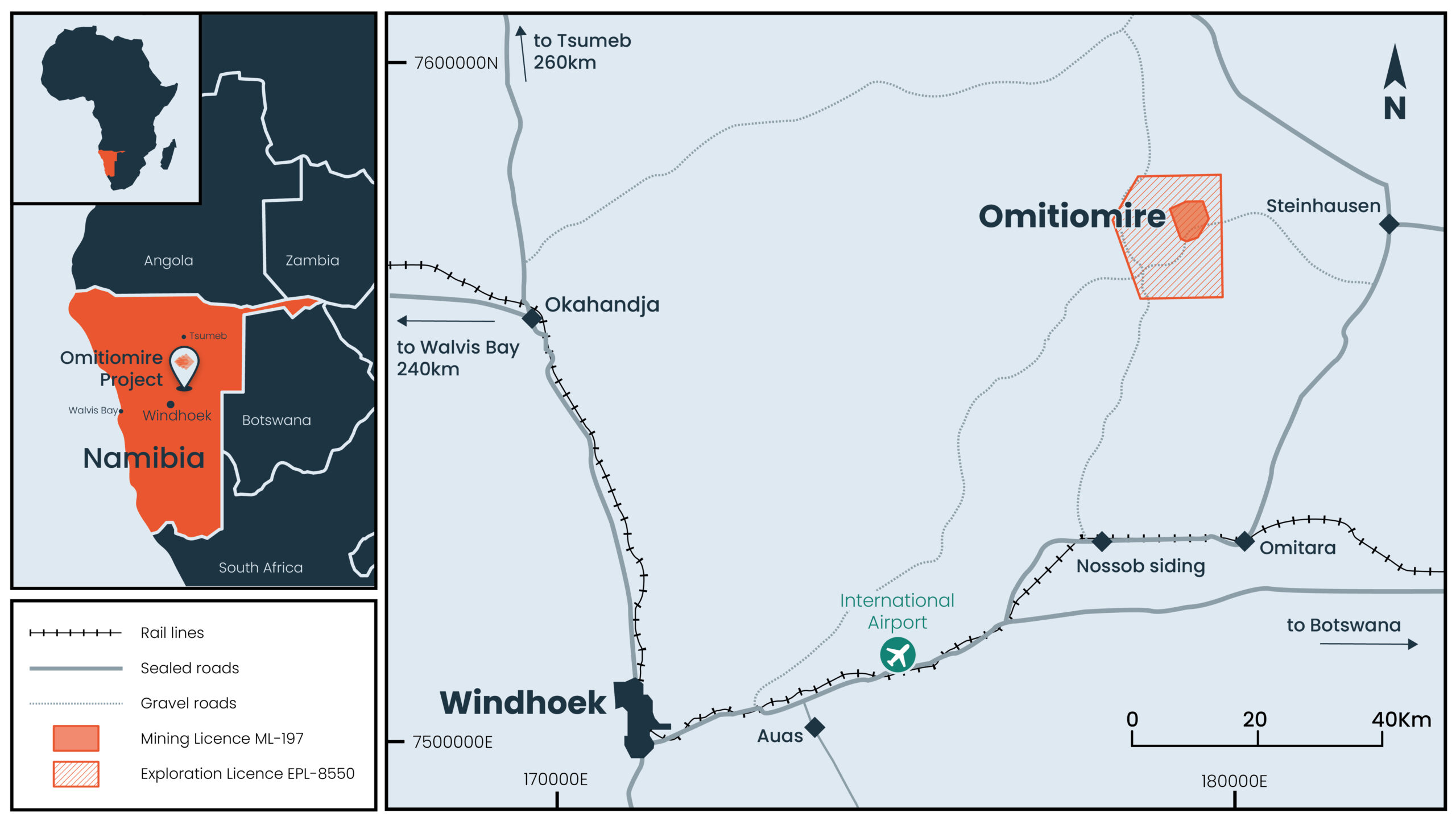

The Omitiomire Copper Project is located 140km by road northeast of Windhoek in central Namibia.

Via its subsidiary, Craton Mining and Exploration (Pty) Ltd, Omico holds Mining Licence ML197, and Exclusive Prospecting Licence EPL8550, together a 304 km2 licence area which makes up the Omitiomire Copper Project.

The Bankable Feasibility Study completed in 2024 included four phases of metallurgical test work over three years and 25 full-size heap leach columns. The final results have delivered significant economic benefits driven by low acid consumption (9kg/t) and short leach times (119 days).

- Low acid, high Cu irrigation solution environment

- Significantly reduced acid consumption and resulting decrease in project capex and opex

- Reduced leach times

Omitiomire Licence

- Mining Licence (ML 197) granted March 2016 for 20 years (renewable)

- Exploration license (EPL8550) granted Sept 2022 for 3 years (renewable for up to 7 years in total)

- Environmental Clearance Certificates granted to September 2025 (renewable) for exploration on both the ML and EPL